How do Circuit Boards Work?

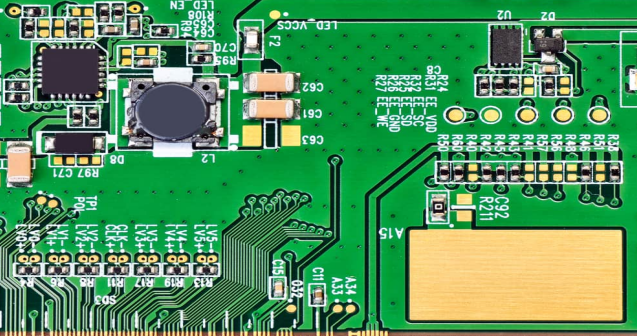

Circuit boards, also known as printed circuit boards (PCBs), are essential components in electronic devices. They provide a platform for connecting and supporting various electronic components to create a functional circuit. Here’s a basic overview of how circuit boards work:

Base Material: The foundation of a circuit board is a non-conductive substrate, usually made of fiberglass or other composite materials. This substrate provides mechanical support and insulation.

Copper Layers: Thin layers of copper are laminated onto the substrate. These copper layers serve as the conductive paths for the flow of electric current. The arrangement of these copper traces forms the circuit pattern.

Components: Electronic components, such as resistors, capacitors, transistors, and integrated circuits, are mounted onto the circuit board. These components are connected to the copper traces according to the circuit design.

Soldering: The components are attached to the board using a process called soldering. Solder, a metal alloy with a low melting point, is used to create a strong and reliable electrical connection between the component leads and the copper traces.

Traces and Pads: Copper traces on the board connect the various components, forming the electrical pathways that allow current to flow through the circuit. Pads are areas of exposed copper where components are soldered.

Layers: Modern circuit boards often have multiple layers of copper traces stacked on top of each other. These layers are interconnected through drilled holes called vias, allowing for more complex and compact circuit designs.

Insulating Layers: Insulating layers, usually made of a material like epoxy resin, separate the conductive layers to prevent short circuits. These layers also provide additional mechanical support to the board.

Silkscreen and Legend: Circuit boards often have a silkscreen layer that includes labels, symbols, and markings for component placement. The legend layer provides information about component values, reference designators, and other details.

Testing and Quality Control: After assembly, circuit boards undergo testing to ensure that all connections are correct and functional. Automated testing equipment can check for electrical continuity and detect potential issues

In summary, circuit boards serve as the backbone of electronic devices, providing a structured platform for connecting and organizing electronic components. The design and layout of the circuit board are critical to the proper functioning of the electronic circuit.

Fubon Precision is serving the PCBA industry since 13 years by providing cost effective solutions for low to high volume demands. Being equipped with state of the art production and inspection equipment and trained professionals for the above steps, Fubon Precision is emerging as global partner for technology innovators. Fubon Precision project management exposure with international partners ensures smooth flow of the projects. Meeting high quality standards and on time completion of projects distinguishes Fubon Precision among other competitors.