Description

Stringent Quality Control

Our SMT assembly process strictly follows high standards and complies with ISO9001, IPC, and UL. We apply several testing and inspection methods to guarantee the high quality of each PCBA, including AOI, x-ray testing, functional testing, etc.

Fast Turnaround Time

Leveraging our state-of-the-art equipment, we deliver PCBA within your deadlines. Our SMT assembly lines offer high productivity and very high flexibility that allows us to effectively engage in all of our customer requests.

Competitive Prices

In-house manufacturing enables us to control the quality and costs as well. In addition, we have reliable suppliers who offer qualified materials at lower prices. Therefore, we can offer customers more competitive prices while maintaining quality.

Excellent Customer Service

We not only provide PCB assembly services, but more importantly, we are your reliable partner who can provide full lifecycle services. Our professional support team offers 24/7 online service to ensure that all your questions are satisfactorily resolved.

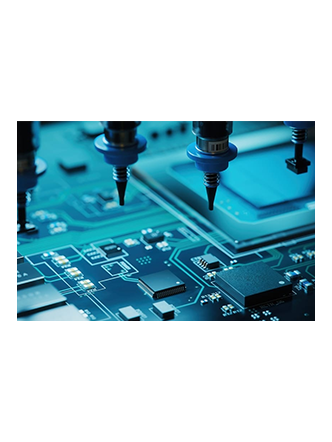

SMT Assembly

Surface-mount Technology, or SMT, is an assembly and manufacturing technique that places electrical components directly on a printed circuit board’s surface (PCB). A greater portion of the assembly work required to create a working circuit can be accomplished with the help of automated production. A surface-mount device is any electrical component installed in this way (SMD). In contrast to conventional assembly, does not call for the insertion of components through holes. Instead, components are connected onto board directly using reflow soldering.

Due to the precision needed to produce high-quality surface mount assemblies, the process can be laborious and time-consuming if performed manually (SMA). Therefore, automated assembly machines are used for the majority of SMT manufacturing to increase efficiency, particularly when production is large-scale.

SMT Assembly Procedure

1, Printing using solder paste

A solder paste printer is used to carry out solder paste printing, and it is positioned at the start of the SMT assembly production line.

2, Chip Mounting

Chip mounting, which is carried out on a chip mounter that is positioned after the solder paste printer in the SMT assembly manufacturing line, seeks to install components onto matching spots on PCB that are compatible with design files.

3, Reflow Soldering

Surface Mount Components or Surface Mount Devices (Surface Mount Components or Surface Mount Devices) are adhered to the PCB board. With the help of cooled solder paste during the reflow soldering process. In the manufacturing process, the reflow soldering oven is situated after the chip mounter.

4, Cleaning

Cleaning machines are typically used to remove residues from SMT assembly manufacturing lines if they are not fixed in place. Cleaning can be done off the line or while the process is running.

5, Inspection

During the PCB assembly process, inspection is utilized to ensure that the soldering and assembly quality is in compliance with the relevant manufacturing standards and laws. If necessary, inspection equipment can be positioned in any appropriate position.

6, Rework

Rework is used to repair or recreate PCBs whose flaws were discovered during the inspection. Rework can be added to the PCB assembly line at any position.

SMT Development Trend

- Flexible and Fast-Responsive.

- Green and environmentally responsible.

- Intelligent and High-Efficiency.