Description

According to the construction and design, aluminum PCBA can be divided into different types. After studying all following types, we can see that aluminum PCBA have many characteristics in same, such as that the main purpose is to provide heat dissipation solutions for the applications involving high temperature.

The multiplayer Aluminum PCB is typical one in power supply applications with multiple layers of thermally conductive dielectrics. These materials are very useful when they are combined with one or more layer of circuitry in which thermally conductive dielectric is buried between the layers with the help of blind vias which also act as a signal or thermal vias. It’s extremely helpful when provide an ideal solution for many applications concerning heat dissipation.

As a new addition in the development of aluminum products, flexible aluminum PCBA increasingly be applied in heat dissipation products. These materials come with polyimide resin integrated with ceramic filters which exhibit high flexibility, thermal efficiency and excellent electrical insulation. When it applied with aluminum material, the final product will save costly cables and connectors, and will bring more flexibility.

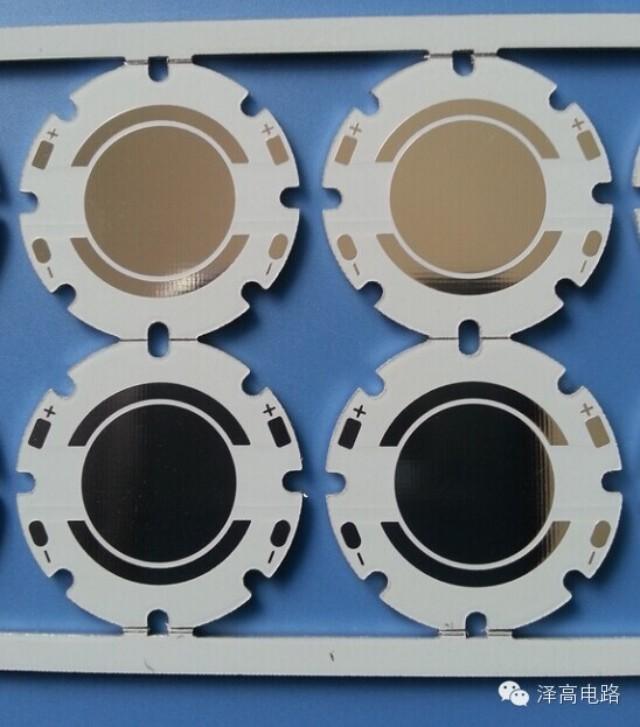

When it comes to more complex constructions, as the production of through Hole Aluminum PCB, a single layer of aluminum is back-filled and pre-drilled with before applying lamination, forming a core of multiplayer constructions. Thermal bonding materials are then used to laminate the thermal materials on both sides of the aluminum. Once lamination is done, drilling is applied on the assembly. In order to maintain proper electrical insulation, the plated through holes are created as the result of drilling must pass through aluminum clearances.

Advantages and applications of aluminum PCBA

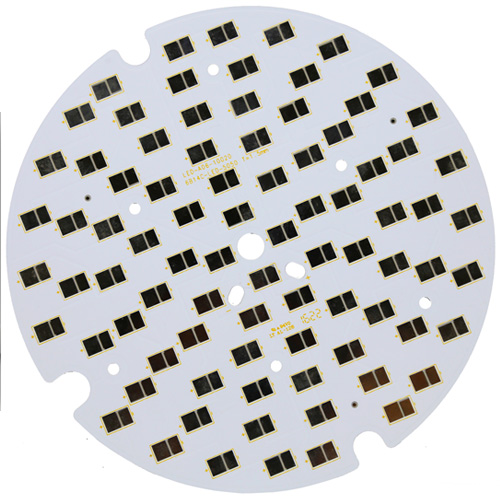

Aluminum PCBA consist of a metal-based, copper-clad laminate that delivers high performance, including excellent thermal conductivity and electrical insulation.

Advantages of Aluminum PCBA

•High level of heat dissipation

The aluminum PCB is better than FR4 based PCB in heat dissipation, it will be ideal choices for the products concerning high pressure and temperature.

•Low Cost

Aluminum is a common mental that can be found in a variety of situation, and it can be mined and refined easily. These benefits make aluminum economical and effective in the numerous applications.

•Environmentally Friendly

Aluminum is non-toxic and recyclable. Using aluminum PCBA help to maintain the health of our planet.

•Higher durability

When it comes to manufacturing, handling and everyday using, aluminum based products provide higher strength and durability than other metal materials.

•Light weight

Surprisingly, with so many improvements in performance, aluminum is a light weigh mental, that add strength and durability without adding any additional weigh.

Applications of Aluminum PCBA

Telecommunications, including high-frequency amplifiers and filtering appliances

Power Supply, such as switching regulators and DC/AC converters

Automotive, including electronic regulators, lighting and power controllers

Computers, such as CPU boards, floppy drives and power devices

Power Modules, including converters, solid-state relays, power rectifiers, and bridges

Audio Devices, such as input and output amplifiers and power amplifiers

Office Automation, such as electric motors and drives

Consumer: Street lighting, Traffic control lighting, Interior building lights, Landscape lighting, and Camping gear.

Medical: Operating room lighting, Surgical lighting tools, High power scanning technology, and Power converters.

Additional information

| PCB Item | Manufacture Capacity |

|---|---|

| Layer Counts | 1–64L |

| Base Material | Aluminum |

| Material Thickness(mm) | 0.40,0.60,0.80,1.00,1.20,1.50,1.60,2.0,2.4,3.0 |

| Max board size(mm) | 1500x400mm |

| Board Outline Tolerance | ±0.15mm |

| Board Thickness | 0.4mm-3.0mm |

| Thickness Tolerance | ±8% |

| Minimum line/space | 0.2mm |

| Min Annular Ring | 0.2mm |

| SMD Pitch | 0.3mm |

| Min Hole Size(mechanical) | 0.3mm |

| Min Hole Size(laser hole) | 0.2mm |

| Hole Size Tol(+/-) | PTH:±0.075mm;NPTH:±0.05mm |

| Hole Position Tol | ±0.075mm |

| HASL/LF HAL | 2.5um |

| Immersion Gold | Nickel 3-7um Au:1-5u" |

| Surface Finish | HAL,ENIG,Plated Gold,Immersion Gold,OSP |

| Copper Weight | 0.5–602 |

| Solder mask | Green, Blue,Black,White, Yellow, Red, Matt Green, Matt Black, Matt Blue |

| Slk screen | White, Black, Blue,Yellow |

| Acceptable File Format | Gerber fle,Powerpcb,CAD,AUTOCAD,ORCAD,P-CAD,CAM-350,CAM2000 |

| Certificate | ROSH,ISO9001 |