Description

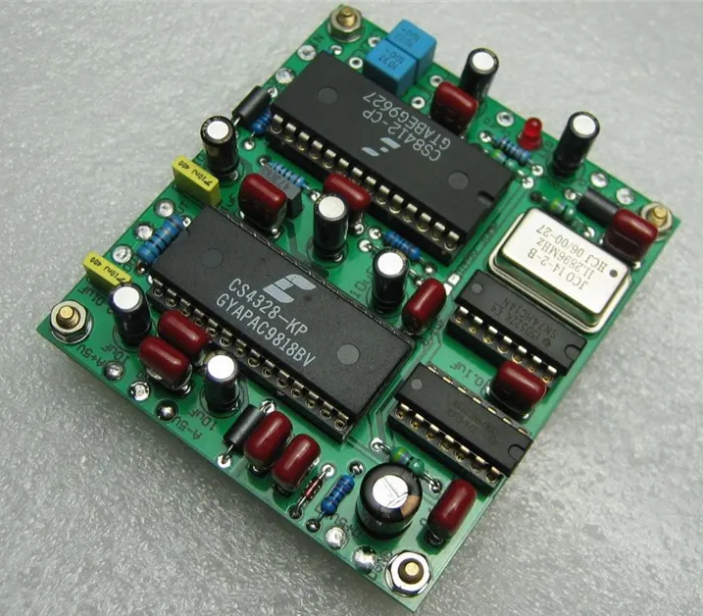

The application and development of medical PCBA continue to develop with medical devices. The most common ones in medical PCBA include:

Medical ultrasound systems, blood analyzers, endoscopic imaging systems, arteriosclerosis testers, MRl equipment, CT scanners, ventilators,etc, the core of these medical equipment is PCB. Medical PCBA end to be specialized high-density interconnect PCBA that will stimulate the growth of high-density interconnect (HD) PCBA in the market PCB assembly applications in the medical and health sector include

| Medical PCBA Assembly Capabilities | |

| at Fubon Precision | |

| PCB Types | Rigid, Flexible, and Rigid Flex PCBs. MCPCBs, Ceramic PCBs, and Rogers PCBs. |

| Layer Count | We can assemble 1 to 40 layers. (Or according to client requirements) |

| Surface Finishes | Gold Plated, Lead or Lead-free, OSR etc. |

| Assembly Options | You can ask for THT SMT hybrid or both. Plus, you can go with single and double-sided placement. |

| Repair & Rework | Repairing and reworking is a very difficult job. You can still contact our team for a better solution. |

| SMT Production Capacity | We are capable to produce 10 million chips per day in the case of 5 SMT lines. And, 8 million per day in the case of 0402 and 0201. |

| DIP Production Capacity | The company can produce 1.2 million pcs per day for 3 Production Lines. |

| Enclosure assembly | 3 Production Lines for enclosure assembly(Each line has 15 assemblers and 2 quality control engineers) |

| Fine pitch assembly | down to 01005,0201 size |

| High accuracy placement | down to 4mil(0.1mm) pitch devices |

Applications

Medical ultrasound system PCB assembly:

medical devices developed according to the principle of ultrasound and used in the medical and health field to diagnose and treat diseases

Hematology analyzer PCB assembly:

Hematology analyzer, also known as hematology analyzer blood cell analyzer, blood cell counter, etc.is one of the most widely used instruments in hospital clinical testing

PCB assembly of endoscope imaging system:

The endoscope generally has the characteristics of steerability and bending, which can penetrate into the cavity or conduct a more detailed all-round observation through the elbow.

PCB assembly of arteriosclerosis tester:

Arteriosclerosis detector is a device that realizes he early examination of arterial function and cardiovascular and cerebrovascular diseases. Regular inspection of arteriosclerosis degree is an important measure for cardiovascular disease prevention

Nuclear magnetic resonance equipment PCB assembly:

It is an imaging technology that collects the signals generated by the magnetic resonance phenomenon and reconstructs the image,so it is also called nuclear magnetic

resonance CT.

CT Scanner PCB Assembly:

CT scanners typically use PCB-based electronics.

Medical wearable PCB Assembly:

Portable medical or health electronic devices that can be worn directly on the body

Ventilator PCB assembly:Ventilators are increasingly used in emergency and critical rescue, anesthesia, postoperative recovery, respiratory therapy and respiratory maintenance. and occupy an important position in medical equipment.

Medical Devices Assembly Service by Fubon Precision

Manufacturing

The production of Medical PCBA should at the very least follow a certified quality assurance system, with the components adhering to responsive AEC standards and the manufacturing and assembly of Medical PCBA adhering to IPC standards. It is abhorrent to do these on your own, therefore why not leave PCB manufacturing, assembly, and electronic component procurement to a reputable Medical PCB manufacturer? Contact Fubon Precision if you haven’t finished your Medical PCB design so that our solution specialists can offer helpful advice and solutions.

Additional information

| PCB Types | Rigid, Flexible, and Rigid Flex PCBs. MCPCBs, Ceramic PCBs, and Rogers PCBs. |

|---|---|

| Layer Count | We can assemble 1 to 40 layers. (Or according to client requirements) |

| Surface Finishes | Gold Plated, Lead or Lead-free, OSR etc. |

| Assembly Options | You can ask for THT SMT hybrid or both. Plus, you can go with single and double-sided placement. |

| Repair & Rework | Repairing and reworking is a very difficult job. You can still contact our team for a better solution. |

| SMT Production Capacity | We are capable to produce 10 million chips per day in the case of 5 SMT lines. And, 8 million per day in the case of 0402 and 0201. |

| DIP Production Capacity | The company can produce 1.2 million pcs per day for 3 Production Lines. |

| Enclosure assembly | 3 Production Lines for enclosure assembly(Each line has 15 assemblers and 2 quality control engineers) |