Description

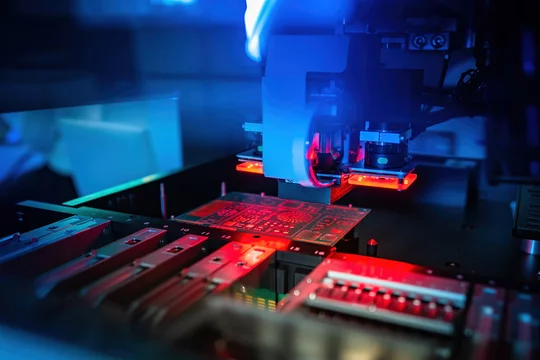

Our Rapid PCB Assembly Services

1, Free DFM & DFA Check

Best technology will provide free PCB file checks to make sure there are no missing components or incorrect construction, and check that these file designs are within the capabilities of our production process.

2, Cost Optimization

Are your prototype designs fully optimized?Our team of manufacturing experts will provide recommendations to cost reduction for you.

3, Consistency

Our prototypes are built under the same ISO-9001-2015 and IPC quality standards as production jobs. We can maintain that consistency over large volumes.

4, PCB Reverse Engineering

We also offer reverse engineering of existing assemblies.

We can take an existing board from a bare board, an assembled board, existing drawings, and we can create a new design with all supporting documentation

5, Quality Control

We have a set of strict quality control system to ensure that every process will be carried out in accordance with IPC standards. We provide our customers with PCB prototypes that exactly meet customer needs and meet the highest quality standards.

Additional information

| Layer Count | 1 – 64 Layers |

|---|---|

| Max Board Dimension | 24*24" (610*610mm) |

| Min Board Thickness | 0.1mm – 2.0mm |

| Max Board Thickness | 6.0mm – 8.0mm |

| Copper Thickness | Outer Layer:1oz~30oz, Inner Layer:0.5oz~30oz |

| Min Line Width/Line Space | Normal: 4/4mil (0.10mm); HDI: 2/2mil (0.05mm) |

| Min Hole Diameter | Normal: 8mil (0.20mm) ; HDI: 4mil (0.10mm) |

| Min Punch Hole Dia | 0.1" (2.5mm) |

| Min Hole Spacing | 12 mil (0.3mm) |

| Min PAD Ring(Single) | 3mil (0.075mm) |

| PTH Wall Thickness | Normal: 0.59mil (15um); HDI: 0.48mil (12um) |

| Min Solder PAD Dia | Normal: 14mil (0.35mm); HDI: 10mil(0.25mm) |

| Min Soldermask Bridge | Normal: 8mil (0.2mm); HDI: 6mil (0.15mm) |

| Min BAG PAD Margin | 5mil (0.125mm) |

| PTH/NPTH Dia Tolerance | PTH: ± 3mil (0.075mm) ; NPTH: ±2 mil (0.05mm) |

| Hole Position Deviation | ±2 mil (0.05mm) |

| Outline Tolerance | CNC: ± 6mil (0.15mm); Die Punch: ± 4mil (0.1mm); Precision Die: ± 2mil (0.05mm) |

| Impedance Controlled | Value>50ohm: ±10%; Value≤50ohm: ±5 ohm |

| Max Aspect Ratio | 8:1 |

| Surface Treatment | ENIG, Flash Gold, Hard Gold Finger, Gold Plating(50mil), Gold finger, |

| Soldermask Color | Green/White/Black/Yellow/Blue/Red |