Description

Additional information

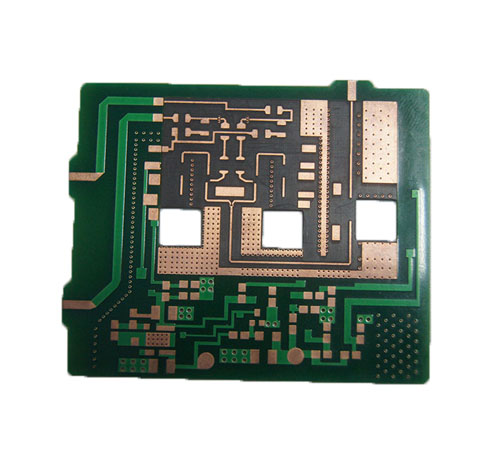

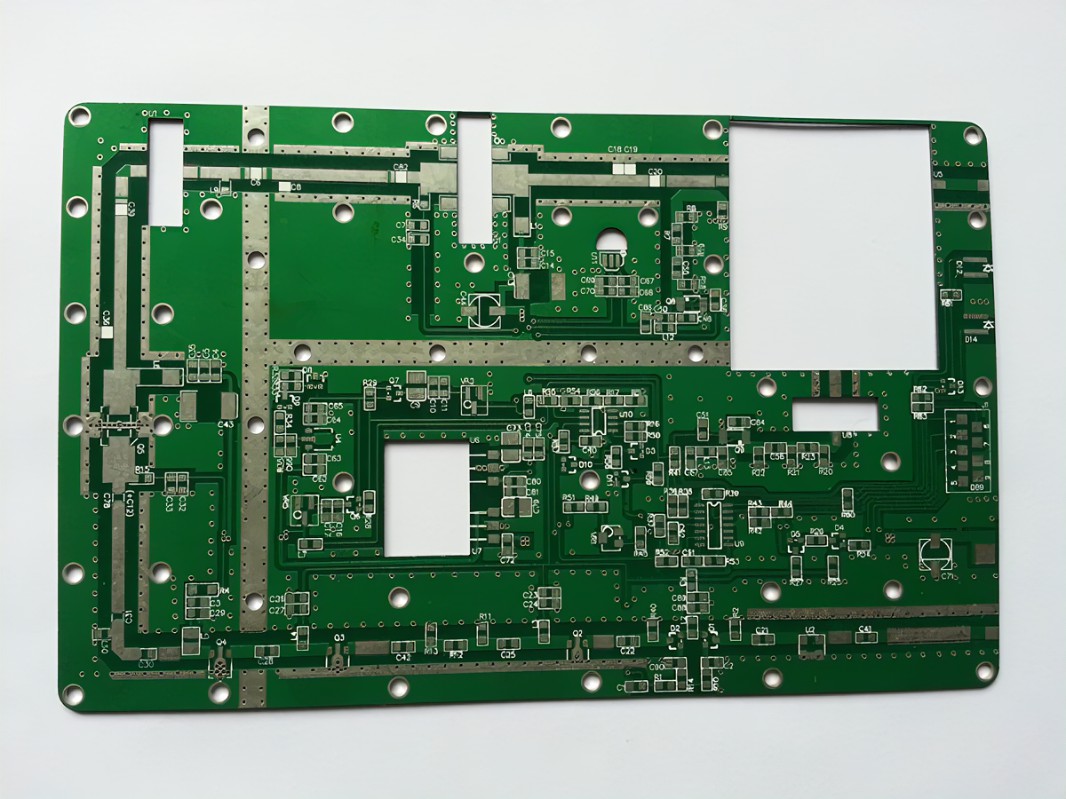

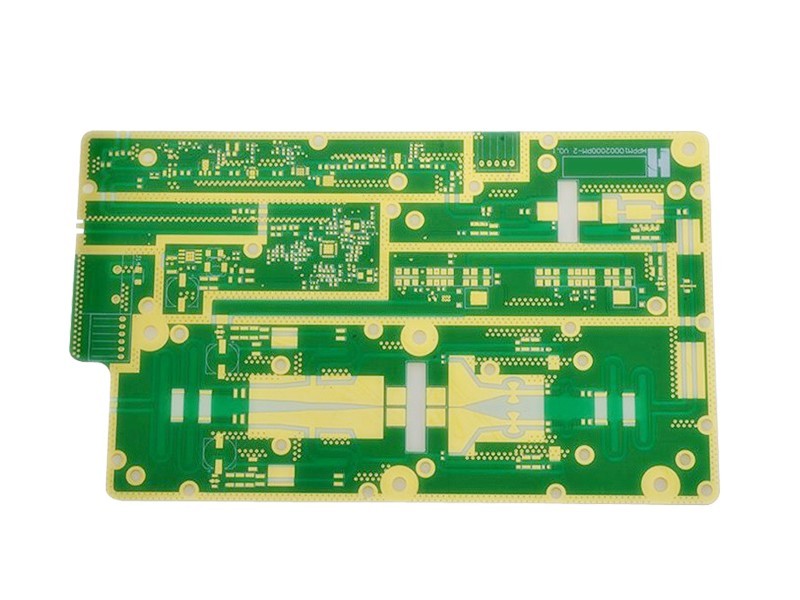

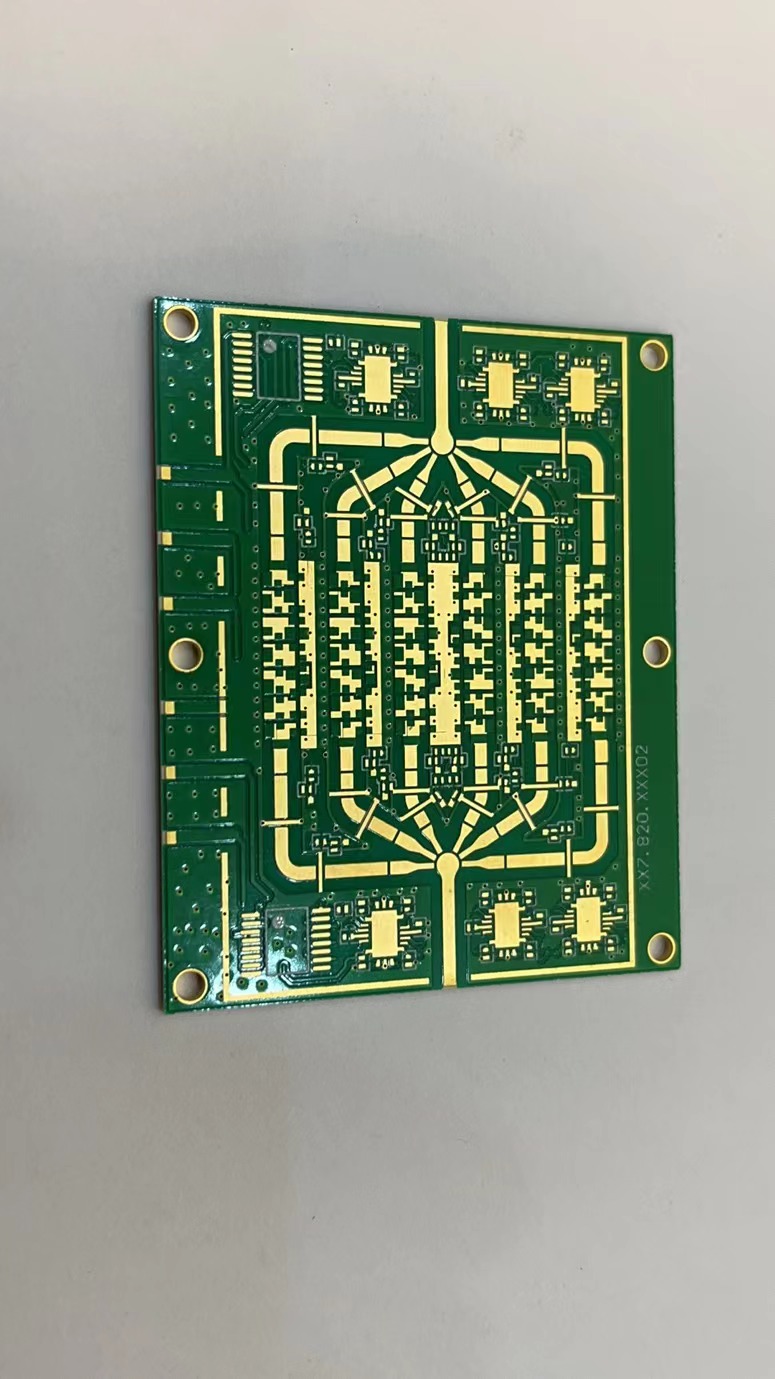

| PCB Item | Manufacture Capacity |

|---|---|

| Layer Counts | 1–20L |

| Base Material | High Frequency(Rogers,Taconic,Aron,PTFE,F4B) |

| Material Thickness(mm) | 0.40,0.60,0.80,1.00,1.20,1.50,1.60,2.0,2.4,3.0 |

| Max board size(mm) | 1500x400mm |

| Board Outline Tolerance | ±0.15mm |

| Board Thickness | 0.4mm-3.0mm |

| Thickness Tolerance | ±8% |

| Minimum line/space | 0.2mm |

| Min Annular Ring | 0.2mm |

| SMD Pitch | 0.3mm |

| Min Hole Size(mechanical) | 0.2mm |

| Min Hole Size(laser hole) | 0.1mm |

| Hole Size Tol(+/-) | PTH:±0.075mm;NPTH:±0.05mm |

| Hole Position Tol | ±0.075mm |

| HASL/LF HAL | 2.5um |

| Immersion Gold | Nickel 3-7um Au:1-5u" |

| Surface Finish | HAL,ENIG,Plated Gold,Immersion Gold,OSP |

| Copper Weight | 0.5–602 |

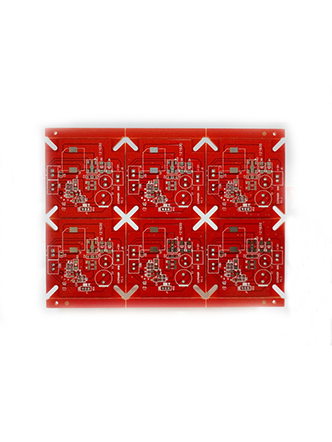

| Solder mask | Green, Blue,Black,White, Yellow, Red, Matt Green, Matt Black, Matt Blue |

| Slk screen | White, Black, Blue,Yellow |

| Acceptable File Format | Gerber fle,Powerpcb,CAD,AUTOCAD,ORCAD,P-CAD,CAM-350,CAM2000 |

| Certificate | ROSH,ISO9001 |