Description

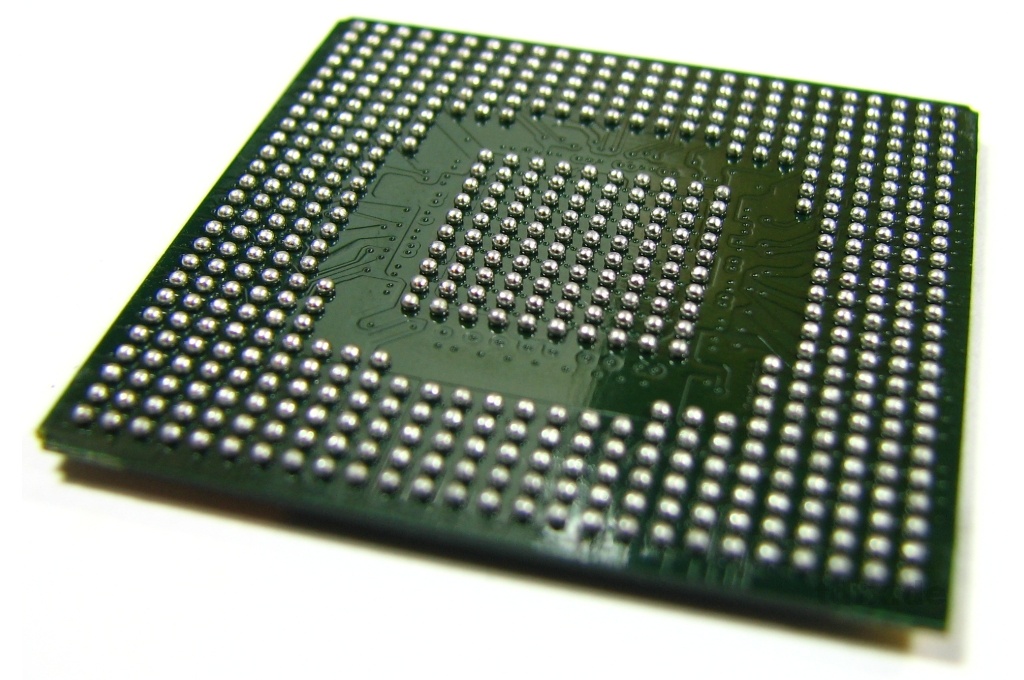

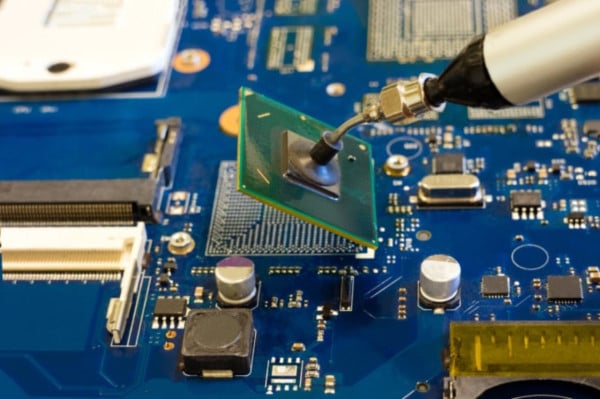

Ball grid array, sometimes known as BGA, is a type of packaging used it to mount components with hundreds of pins, such as microprocessors. BGA assembly is the process of directly mounting the BGA packages or integrated circuits (ICs) onto BGA board and soldering them in place. SMD assembly is the same as the process of constructing an SMD package. However, unlike SMD assembly, BGA soldering requires exact control and is carried out by automated procedures.

Full Coverage BGA PCB Assembly Services

Fubon Precision BGA assembly services cover a wide range, including BGA prototype development, BGA PCB assembly, BGA component removal, BGA replacement, BGA rework and reballing, BGA PCB assembly inspection, and so on. Leveraging our full-coverage services, we can help customers streamline the supply network and accelerate product development time.

Stringent BGA PCB Assembly Testing Process

To achieve the highest quality standards for BGA assembly, Fubon Precision use a variety of inspection methods throughout the process including optical inspection, mechanical inspection, and X-ray inspection. Among them, the inspection of BGA solder joints must use X-rays. X-rays can pass through the components to inspect the solder joints below them, so as to check the solder joint position, solder joint radius, and solder joint thickness.

Benefits of BGA PCB Assembly

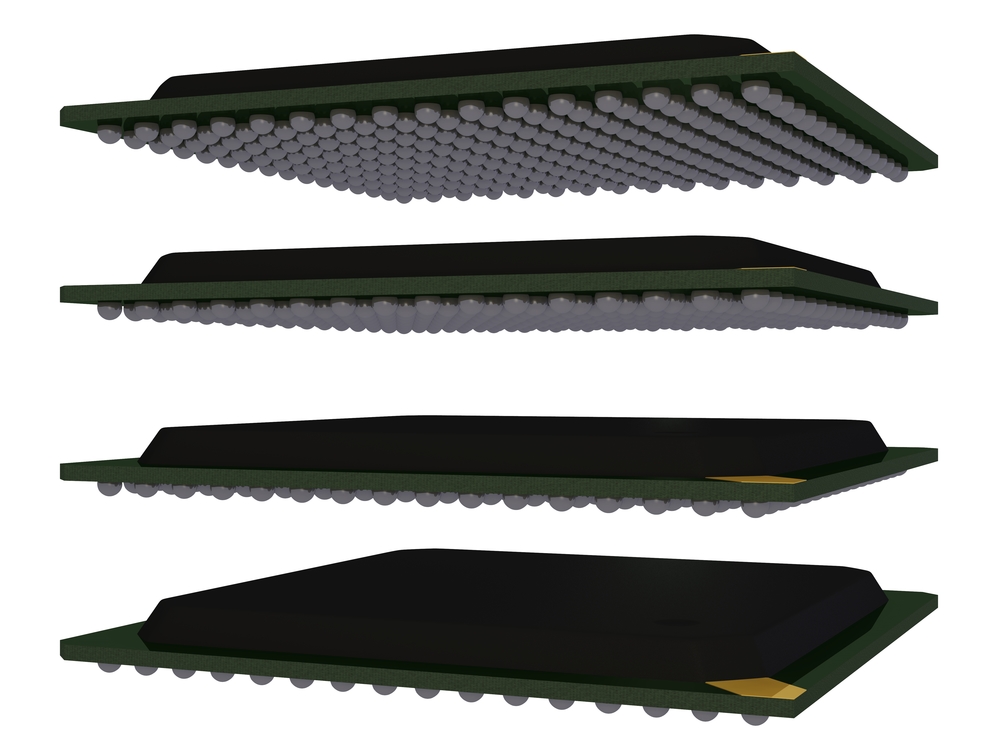

Efficient Use of Space – BGA PCB layout allows us to efficiently use the available space, so we can mount more components and manufacture lighter devices.

Better Thermal Performance – For BGA, the heat generated by the components is transferred directly through the ball. In addition, the large contact area improves heat dissipation, which prevents overheating of components and ensures long life.

Higher Electrical Conductivity – The path between the die and the circuit board is short, which results in better electrical conductivity. Moreover, there is no through-hole on the board, the whole circuit board is covered with solder balls and other components, so vacant spaces are reduced.

Easy to Assemble And Manage – Compared to other PCB assembly techniques, BGA is easier to assemble and manage as the solder balls are used directly to solder the package to the board.

Less Damage to Leads – Fubon Precision use solid solder balls for manufacturing BGA leads. Hence, there is a lesser risk that they will get damaged during the operation.

Application of solder paste in BGA Assembly

Without the use of solder paste, BGA rework is frequently accomplished and is typically more reliable (i.e., using only the solder balls). This presupposes that the site preparation and fluxing procedures were honest. Solder paste is frequently useful in situations where there may also be planarity problems.