Description

With the shortest lead times available, turnkey PCB assembly is an electronic assembly solution that provides effective and economical ways to build and test circuit boards with new products. You can move from design to working prototype in as little as a few working days with the help of our full-service PCBA prototyping service. The most creative small enterprises and startups frequently discover that, when it comes to building those printed circuit boards (PCBs), they encounter some difficulties, such as the requirement to maintain a sizable inventories and to have an in-house team to create it.

Turnkey PCB process

Turnkey PCB assembly is a kind of EMS (electronic manufacturing services) service provided by PCBONLINE, which manufactures end electronic products or parts of a product of our clients’. The process of our turnkey PCB assembly service is as below when you order from us.

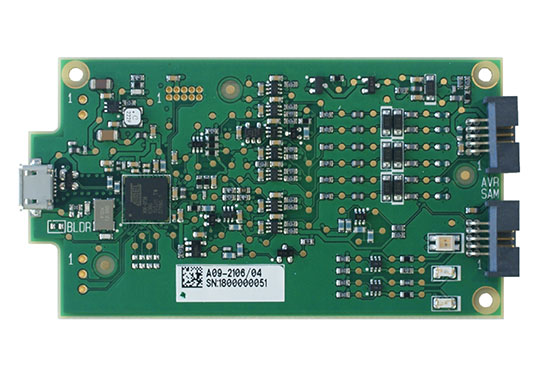

Step 1. PCB manufacturing

When getting the Gerber files, drill files, and BOM from you, we check them immediately and then give a quotation to you in a quick manner. When you confirm, we start to manufacture the PCBs. If you don’t have a Gerber file but only your requirements, we can also produce the PCBs meeting your requirements. PCBONLINE can fabricate all circuit boards for any circuits, but we are featured with the advanced boards. You can order from us without a minimum circuit board quantity limit, and no matter what your requirements are, we can manufacture your PCBs.

Step 2. Component sourcing

We provide all the components in your bill of materials (BOM), including passive components, active components, and custom-made special components. Component sourcing happens simultaneously when we manufacture the PCBs to save time. We have 21 years of PCB manufacturing and component sourcing experience, and we ensure that all components are of the best quality. All the components are high-quality and traceable. Our component warehouse is next to the PCB assembly factory, so we can mount the circuit board parts immediately once we test the component functionality.

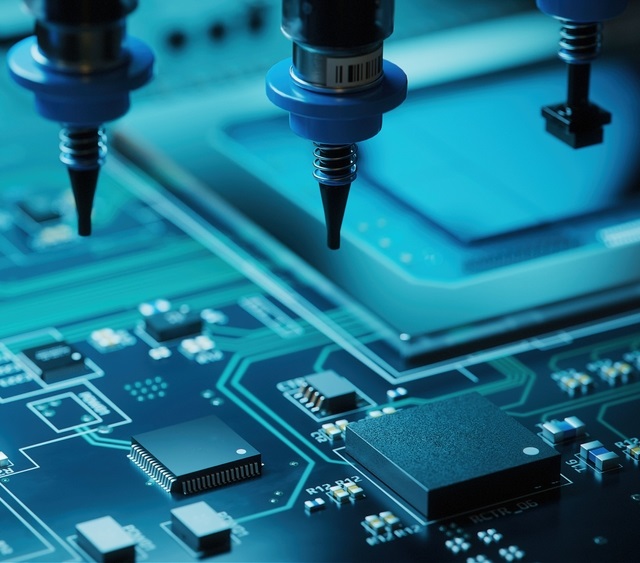

Step 3. PCB assembly

When the PCBs and components are ready, PCBONLINE will mount the components on the circuit boards. Our assembly includes the SMT assembly and THT assembly, and we manufacture the SMT stencils for the assembly. Our assembly machines are advanced, such as the 3D SPI, reflow soldering ovens that can deal with both the lead-free and lead-containing soldering, 3D AOI, first piece tester, and more. The whole operations and solder paste we provide are also RoHS-certified, and you don’t need to worry about the assembly quality. After the assembly, the PCBA functional test and burn-in test are processed to ensure circuit board quality. You can also require any other tests or measurements like spraying three-anti paint.

Step 4. Final assembly

Our EMS service includes the end product assembly, and all you need to provide is only the drawings of the product shell and package. We will manufacture the product shells, assemble the end products, print the electronic product codes, and package them. The packaging includes the instruction, inner packaging, and outer covering. The final assembly is also RoHS-certified. After the final assembly, you will get ready-to-use products.

Step 5. Shipping

Usually we will apply the DHL shipping when we finish the turnkey PCB assembly. When you get the products, the perfect EMS service does not come to an end – you can always contact us if you have any concern, and we will also repair your PCBs and solve any other issues as well. And you are always welcome to keep a long term cooperation with us.

Benefits of Turnkey PCB Assembly

Turnkey PCB assembly’s most obvious advantage is that it spares firms from having to divert their attention from crucial activities like ongoing innovation in order to spend time working out the assembly details.

1, Cost Reduction

You save a lot of money when you use a turnkey contract because it doesn’t cost extra to transfer materials to an assembly workshop.

2, Issue Identification

A significant benefit of PCB assembly is the opportunity to identify any problems before the circuit boards are incorporated into any products, which can save both time and money. You give the assembler a net list file as part of the procedure.

3, Streamlined Management

Dealing with numerous vendors may be time-consuming and frustrating, especially for small organizations with scarce human resources. Due to the fact that turnkey manufacturing solutions manage various channels of communication, there is a far lower possibility of a misunderstanding occurring. These potential misunderstandings could arise between yourself and a vendor or even between two vendors, which could cause a delay in your schedule and cost you money.

Your turnkey provider will probably give you a single point of interaction via which all transactions will be made, ensuring your peace of mind & lessening the administration strain associated with PCB assembly.