Description

What is an SMT Stencil

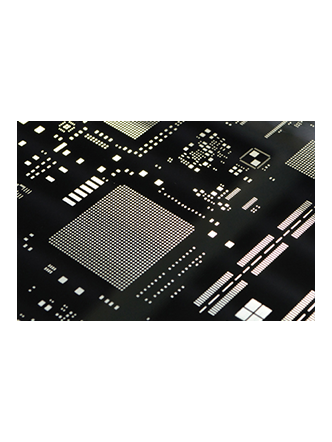

- An SMT stencil, also known as a PCB stencilor solder paste stencil, is a steel stencil made according to the top paste layer and bottom paste layer in your Gerber/IPC-2581. It is manufactured when PCB fabrication happens. The quantity of SMT stencils depends on how many SMT lines you want the PCBA manufacturer PCBONLINE to turn on for your project.

- How is an SMT stencil used in PCB assembly? The stencil is put in an automatic SMT machine, and a scraper with solder paste is pressed on it. Meanwhile, a PCB panel passes under the stencil. In this way, the solder paste leaks through the openingson the SMT stencil and is printed on the required PCB pads. The solder paste thickness falls in the range of ±0.03mm of the stencil thickness.

Benefits of SMT Stencil

- Wide Applications

SMT stencils can be used for almost all PCB manufacturing processes, which are not limited to any specific fabrication technique.

- High Accuracy and Consistency

It ensures that the position of the solder paste pads is highly accurate and the aperture is consistent.

- Shorten PCB Assembly Time

With SMT stencils, the paste can be applied to the entire PCB in one go, reducing the assembly time significantly.

- No Gaps in Soldering Process

Using laser-cut stencils, you can apply a smooth layer of solder past, so there are no gaps in the soldering process.

Types of STM Stencils Available at Fubon Precision

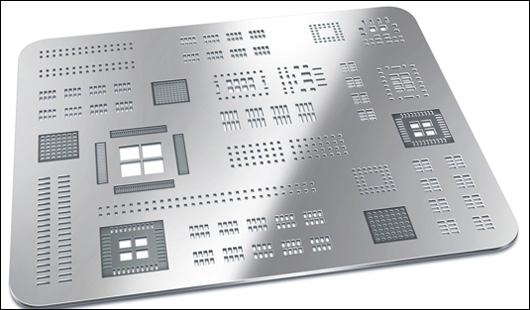

1, Framed SMT Stencil

This kind of SMT stencil is fixed in the frame permanently, with the aid of a mesh border, the stencil foil can be stretched tightly which is conducive to high-accuracy printing. Compared to a frameless SMT stencils, it is more convenient as there is no need to stretch the stencil by yourself, and it is more suitable for high-volume production runs.

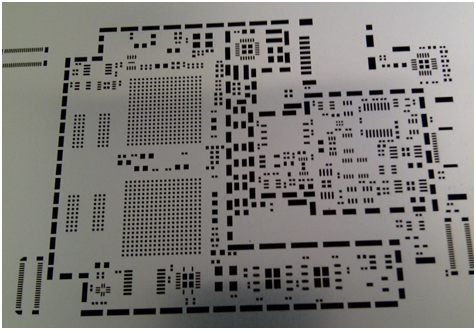

2, Frameless SMT Stencil

Frameless stencils or foils are 100% laser-cut sheets. you can use them in reusable frames. Comparatively, it offers a cost-effective and environmentally friendly solution. As a result, it is best for short runs and prototype PCB assembly. Furthermore, you can use it for both hand and machine soldering.

3, Prototype SMT Stencils

These stencils are made from CAD files or Gerber files and designed for hand-solder paste printing. Using prototype SMT stencils, can eliminate printing mistakes, and save you from soldering components on the circuit board to speed up the PCB assembly process.

4, Electroformed SMT Stencils

If you require the stencil for the most precise applications, Electroformed SMT stencils are the best solution for you. They are stencils made with electroformed foils, the raw material is nickel. The initial costs of this kind of stencil are high though, and it requires longer processing time than other stencils.