Description

Your fridge is talking to your phone, while the lights are being turned off based on your habits and the window shades taking care of themselves. The smart everything and connected devices era have facilitated lots of tasks we previously had to take care of, ourselves. With expertise in telecommunication protocols making the “everything smart” possible, we make the connected world a reality, daily.

Making the connected world a reality, starting with your home.

Smart home devices and equipment are redefining the way we live. With so many options at our fingertips, the smart everything and connected era have brought more and more electronics devices into our daily lives, automating lots of tasks we now take care of, remotely.

Smart home devices and connected devices overall, are nothing new to the electronics industry: it is simply a miniaturization of existing systems (previously used in industrial environments), combined to the increasing use of data and a more consumer oriented human/machine interaction.

We, at Asteelflash, are experts in smart home manufacturing services. Thanks to our smart factories, our engineers and machines use big data analysis, cloud computing, artificial intelligence (AI) and 3D-printing to create connected devices for smart home.

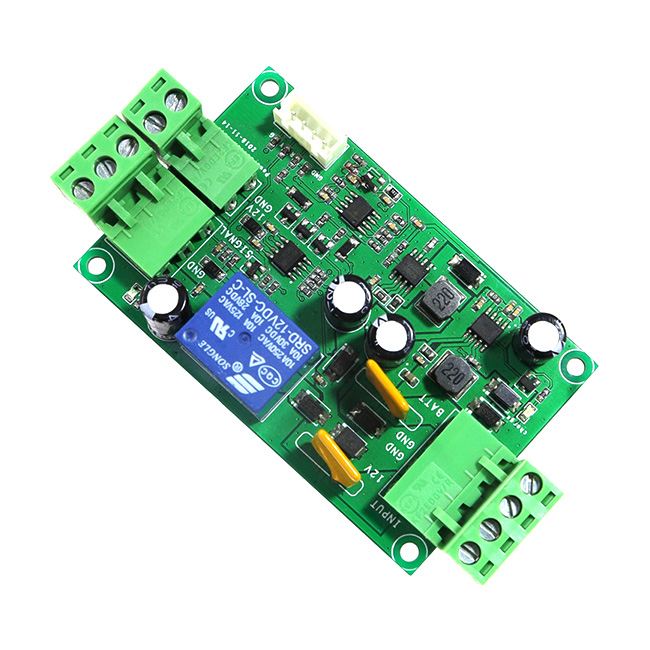

From design and PCB board manufacturing to NPI services and end-to-end product lifecycle solutions, our smart factories can bring smart supply chain solutions to our customers, for all their smart home devices.

| Smart home PCB Assembly Capabilities | |

| at Fubon Precision | |

| PCB Types | Rigid, Flexible, and Rigid Flex PCBs. MCPCBs, Ceramic PCBs, and Rogers PCBs. |

| Layer Count | We can assemble 1 to 40 layers. (Or according to client requirements) |

| Surface Finishes | Gold Plated, Lead or Lead-free, OSR etc. |

| Assembly Options | You can ask for THT SMT hybrid or both. Plus, you can go with single and double-sided placement. |

| Repair & Rework | Repairing and reworking is a very difficult job. You can still contact our team for a better solution. |

| SMT Production Capacity | We are capable to produce 10 million chips per day in the case of 5 SMT lines. And, 8 million per day in the case of 0402 and 0201. |

| DIP Production Capacity | The company can produce 1.2 million pcs per day for 3 Production Lines. |

| Enclosure assembly | 3 Production Lines for enclosure assembly(Each line has 15 assemblers and 2 quality control engineers) |

| Fine pitch assembly | down to 01005,0201 size |

| High accuracy placement | down to 4mil(0.1mm) pitch devices |

Electronic manufacturing service provider for Smart Home, we manufacture:

Automated door controls and systems

Sensors (Motion, Leak, Intrusion, etc.)

Gateway modules

Communication modules

Smart home central controllers

Controllers

Smart meters

Audio devices and equipment

Security devices and equipment

Smart lighting

Manufacturing

The production of Smart Home PCBA should at the very least follow a certified quality assurance system, with the components adhering to responsive AEC standards and the manufacturing and assembly of Smart Home PCBA adhering to IPC standards. It is abhorrent to do these on your own, therefore why not leave PCB manufacturing, assembly, and electronic component procurement to a reputable Smart Home PCB manufacturer? Contact Fubon Precision if you haven’t finished your Smart Home PCB design so that our solution specialists can offer helpful advice and solutions.

Additional information

| PCB Types | Rigid, Flexible, and Rigid Flex PCBs. MCPCBs, Ceramic PCBs, and Rogers PCBs. |

|---|---|

| Layer Count | We can assemble 1 to 40 layers. (Or according to client requirements) |

| Surface Finishes | Gold Plated, Lead or Lead-free, OSR etc. |

| Assembly Options | You can ask for THT SMT hybrid or both. Plus, you can go with single and double-sided placement. |

| Repair & Rework | Repair & Rework Repairing and reworking is a very difficult job. You can still contact our team for a better solution. |

| SMT Production Capacity | We are capable to produce 10 million chips per day in the case of 5 SMT lines. And, 8 million per day in the case of 0402 and 0201. |

| Enclosure assembly | 3 Production Lines for enclosure assembly(Each line has 15 assemblers and 2 quality control engineers) |

| Fine pitch assembly | down to 01005,0201 size |

| High accuracy placement | down to 4mil(0.1mm) pitch devices |