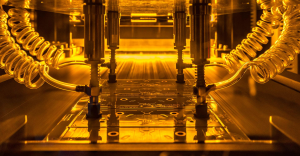

How to make low-cost PCB prototypes for your next project?

What is a PCB prototype & why is it used?

Essentially a PCB prototype is an early sample of the final board. It is required to help test the basic functionality of the PCB board design. PCB prototypes can be of various kinds, such as:

1,Visual Models

2, Working Prototypes

3, Proof-of-concept

4, Functional Prototypes

While a visual model will give a fair idea of the physical aspect of the product, a functional prototype will be close to the final product.

Importantly, a prototype helps with finding out any design flaws at the early stage itself. This results in saving you costly errors at a later stage. The prototype helps test a modern design quickly before you get to the mass production stage.

How to achieve low-cost PCB prototype?

Achieving a low-cost PCB (Printed Circuit Board) prototype involves optimizing the design and production process to reduce expenses without compromising quality. Here are several tips to help you achieve a cost-effective PCB prototype:

Design Optimization:

Size and Complexity: Keep the PCB size and complexity to a minimum. Smaller boards generally cost less.

Layers: Limit the number of layers in your PCB design, as each additional layer increases production costs.

Component Placement: Optimize component placement to reduce the overall size and complexity of the board.

Standard Components: Use standard and readily available components to minimize costs.

PCB Fabrication:

Prototype PCB Manufacturers: Choose a low-cost prototype PCB manufacturer. Many companies specialize in providing affordable prototyping services.

Panelization: If your design allows, panelize multiple PCBs on a single board to take advantage of the manufacturing process, reducing costs per board.

Material Selection: Choose standard PCB materials that are readily available and

cost-effective.

Surface Finish: Select cost-effective surface finishes such as HASL (Hot Air Solder Leveling) instead of gold plating.

Ordering in Bulk:

Volume Discounts: If you plan to build multiple prototypes, consider ordering them in bulk to take advantage of volume discounts.

Group Orders: Join group orders with other designers to collectively reduce manufacturing costs.

DIY Prototyping:

Home Etching: For simple designs, consider etching your PCBs at home using DIY methods. This is more suitable for single-sided or double-sided boards with through-hole components.

Prototyping Boards: Use prototyping boards for small-scale projects where a custom PCB is not necessary.

Open-Source Tools:

EDA Tools: Utilize open-source Electronic Design Automation (EDA) tools for PCB design. Software like KiCad is free and powerful.

Bulk Ordering: Source components in bulk to benefit from quantity discounts.

Alternative Suppliers: Explore different suppliers for components and compare prices.

Testing and Debugging:

Thorough Testing: Ensure your design is thoroughly tested before sending it for production to avoid costly errors.

Iterative Prototyping: If possible, adopt an iterative approach to prototyping, refining your design based on the results of initial prototypes.

Shipping and Customs:

Local Manufacturers: If possible, choose a local manufacturer to reduce shipping costs and avoid potential customs issues

Conclusion

The importance of a PCB prototype cannot be overstated. They can go a long way in reducing the total costs of the project as also its timeline. They are a wonderful way to test your design early as also to test components individually & collectively. They can be used to spot any potential issues early & make the necessary changes. With the right best practices & involvement of professional contract manufacturers you can ensure that the price of the prototype is optimized.