Effective Measures to Improve SMT Assembly Quality

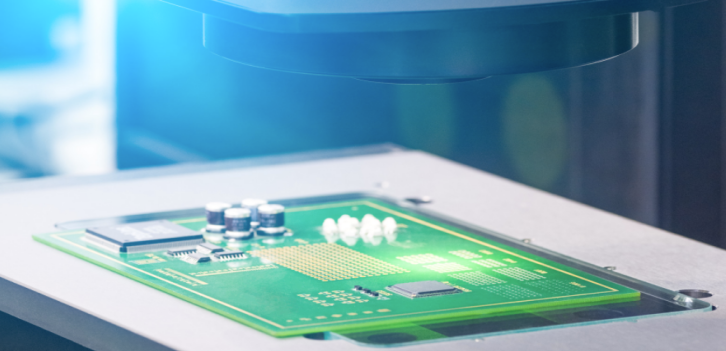

As a key type of PCB assembly manufacturing, SMT (Surface Mount Technology) assembly has been widely applied in electronics industry owing to its capability to reduce material, labor and time cost and advantages of high reliability and high frequency. Up to now, SMT assembly has been applied in almost all industries including aerospace, medical care, computer, telecommunication and automotive, substantially improving people’s life and electronic products’ reliability.

However, one coin has two sides. SMT assembly drives electronics products to feature higher reliability and integrity while end product quality tends to go down if some issues are caused during SMT assembly process. Since the establishment of Fubon Precision in 2010, quality has been the core target of our business and some effective measures to improve SMT assembly quality have been summarized in our workshop due to the accumulation of more than 15 years’ electronics manufacturing experience.

Surface Mount Technology (SMT) assembly is a critical process in electronics manufacturing, and ensuring high-quality SMT assembly is essential for the reliability and performance of electronic products. Here are some effective measures to improve SMT assembly quality:

Design for Manufacturability (DFM):

Begin by designing PCBs with SMT assembly in mind. Consider component placement, orientation, and spacing to minimize the risk of defects during assembly.

Select High-Quality Components:

Use reputable suppliers for SMT components to ensure consistency and reliability. Counterfeit or low-quality components can lead to production issues and reliability problems.

Stencil Design and Printing:

Optimize stencil design for solder paste application. Ensure proper aperture sizes, alignment, and thickness for consistent solder paste deposition.

Implement quality control measures during stencil printing, such as periodic checks and maintenance of the stencil printer.

Component Placement:

Invest in advanced pick-and-place machines with accurate vision systems to ensure precise component placement.

Implement machine vision inspection systems to verify component placement accuracy.

Solder Paste Inspection (SPI):

Use SPI systems to inspect solder paste deposits for defects like insufficient or excessive solder paste. This helps catch issues early in the process.

Reflow Soldering Profile Optimization:

Develop and maintain optimized reflow soldering profiles that suit the specific solder paste and components being used.

Regularly monitor and calibrate reflow ovens to ensure consistent temperature profiles.

Solder Paste and Flux Selection:

Choose high-quality solder paste and flux materials that match your assembly requirements.

Ensure proper storage and handling of solder paste to prevent moisture absorption or other contaminants.

Automated Optical Inspection (AOI):

Implement AOI systems to inspect solder joints and components post-soldering. AOI can identify defects like bridging, tombstoning, or misalignment.

X-ray Inspection:

Use X-ray inspection for non-destructive analysis of hidden solder joints, especially for complex and fine-pitch components.

Operator Training and Certification:

Train assembly personnel to handle components, operate machines, and follow assembly procedures correctly.

Implement a certification program to ensure operators maintain proficiency.

Quality Control and Process Monitoring:

Establish a robust quality control system with regular inspections and process audits.

Monitor process parameters and collect data for continuous improvement.

Traceability and Documentation:

Maintain comprehensive records of components, processes, and test results for traceability and troubleshooting.

Implement barcode or RFID tracking for components and assemblies.

Environmental Control:

Maintain a controlled environment in the assembly area to minimize humidity, temperature fluctuations, and airborne contaminants.

Failure Analysis and Root Cause Investigation:

Develop a systematic approach to investigate and address defects or failures, focusing on root cause analysis to prevent recurrence.

Supplier Quality Assurance:

Work closely with component suppliers to ensure their quality control processes meet your standards.

Continuous Improvement:

Encourage a culture of continuous improvement and innovation within your SMT assembly team.

By implementing these measures, you can enhance the quality of your SMT assembly processes, reduce defects, improve reliability, and ultimately produce higher-quality electronic products. Regularly review and update your processes to stay current with industry best practices and emerging technologies.