Services and Offerings

Fubon Precision Laser Carving

Laser carving is a very common production link in electronics manufacturing. On the one hand, it can be used to mark information of each electronic component, as we all know that most electronic products are composed of amounts of tiny components such as SMD components, to better recognize them, laser carving is a perfect technology that can show the information permanently and supports mass production. On the other hand, it can be applied to custom product housing such as carving a logo or pattern on it.

Fubon Technology offers the latest laser carving technology by using the industry-leading machines, our experienced employees make sure to provide you with the best laser carving service. Contact us today to discover how our technology can help you!

Why Choosing Fubon Precision for Laser Carving?

Rich Experience in Laser Carving

Fubon Precision has been established in 2012 with laser carving experience of more than 11 years, we have provided laser carved products to hundreds of customers around the world. Our professional R&D team has participated in hundreds of projects and has extensive experience.

Fast Turnaround

There are more than 350 employees in Fubon Precision who are all professionally trained, they know how to work efficiently with their skillful operation of the machine and effective communication with clients, to make sure the fast turnaround times.

Trustworthy Partner

Currently, Fubon Precision has obtained certifications including ISO9001:2015, ISO14001, ISO13485, ROHS, BSCI, and UL, which displays our commitment to strict quality control standards. We put our clients into the priority, making sure our products and service can meet if not exceed their requirements.

Amazing Service

Fubon Precision is committed to offering the best customer services to our clients, our friendly and professional sales team is 24/7 available to offer the best solution and quick response to our customers.

Fubon Precision Laser Carving Products

The Advantages of Laser Carving

Laser carving has evolved tremendously over the years, and it has been applied for many industries such as aerospace, medicine, electronics manufacturing, jewellery customization, and so on, believing it will be used more and more frequently and bring more benefits for us in the future. Why is it so popular? That’s because it has many advantages compared to traditional carving, below are listed some key points for your reference:

1. Versatility

Laser carving is suitable for almost all hard materials, unlike other technologies such as printing, you can find objects or materials that can be laser carved without difficulty. Moreover, one laser cutting machine can meet all your customization requirements for any item. This is the main reason why it is such popular.

2. Wear-resistant

The depression in the surface produced by laser carving can last for really a long time, you don’t need to worry about if it would be worn after long-term use. Moreover, the surface that is laser-carved has a great finish and smooth touch.We can see many antiques with carvings, and the carved patterns are still clearly visible after they have been preserved for hundreds of years.

3. High Efficiency

Laser carving is well-known for its high efficiency, in fact, it is a marking process with the fastest production speed currently. As the carving process is automatic and it will not be affected by tool replacement or the lack of labor. The production time is short and the quality of the carving is excellent, for some complex patterns, it only takes a few hours to finish it, so the demand for such technique has increased dramatically in recent years.

4. Accuracy

The pattern is carved by precise laser beams that can maintain the sharpness as always. Unlike traditional mechanical tools, which would be dull after a few time uses and then reduce the accuracy of carving. Laser beams are controlled by computers with precise design and calculation to make sure the carved patterns match your requirement perfectly.

5. Cost-effective

Laser carving has featured with shorter production time, time is money in business, which means the cost would be less including the labor cost. On the other hand, its accuracy reduces the possibility of defective products, there is less need to purchase extra materials as replacements.

During the process of metal injection, the metal waste is less except when mold production and debinding. There is no need to cut away excess material once injecting the feedstock into the mold, so it is also a very environmental technique.

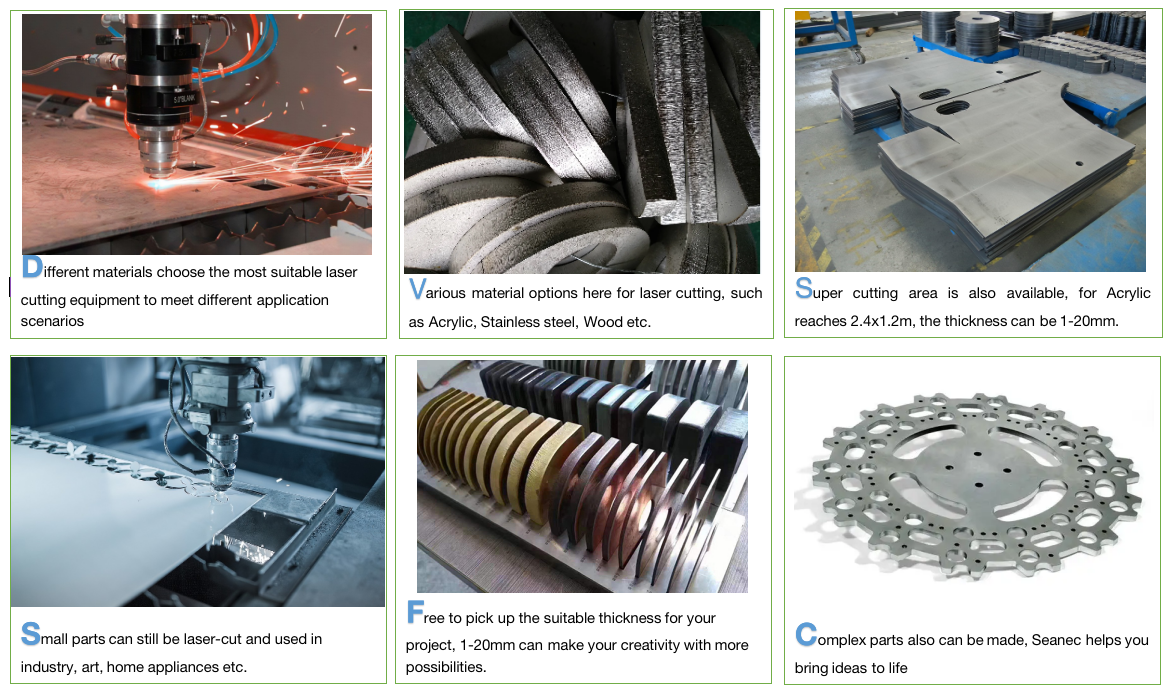

Laser Cutting Service

In order to meet the customer’s demand for product design, Fubon Precision added this Laser Cutting Service,

aiming to help the customer complete the design efficiently. We do our best to satisfy our customers.

Laser Cutting material introduction